Shut-off valves in sewage treatment plants

Efficient solutions for a wide range of applications in sewage treatment plants

Sewage treatment plants play a crucial role in modern water management. They ensure that sewage from households, industry and commerce is treated before it is returned to the environment. A wide variety of media - from wastewater and sewage sludge to air and chemicals - must be controlled safely and efficiently. GEFA offers reliable shut-off valves that are specially designed for the demanding conditions in sewage treatment plants.

Areas of application for our knife gate valves in sewage treatment plants

Sludge treatment

Sludge treatment is a central component of the sewage treatment process. During sewage treatment, large quantities of sewage sludge are produced that require further treatment. Our DOMINO knife gate valves are particularly suitable for viscous thick sludge or gas-carrying digested sludge.

Sewage sludge drying

Sewage sludge is a by-product of sewage treatment and passes through various process stages - from thickening and digestion to dewatering. Our DOMINO high-pressure gate valves are ideally suited for this, as they work reliably even at high pressures and do not clog even with viscous media.

Aeration tanks

Aeration tanks are the heart of biological wastewater treatment. Here, targeted aeration promotes the decomposition of organic substances. Our DOMINO control gate valves enable precise air control for effective oxygen input in aeration tanks and offer considerable energy savings.

Efficient sludge treatment with knife gate valves

Sludge treatment is a central component of the sewage treatment process. During sewage treatment, large quantities of sludge are produced that need to be treated further. Depending on the stage of sludge treatment, shut-off valves must be able to cope with extreme conditions. Our DOMINO knife gate valves are particularly suitable for viscous thick sludge or gas-carrying digested sludge.

DOMINO AT100 (SD1) / AT200 (SD7) - The safe solutions in sludge treatment

GEFA knife gate valves from the AT100 and AT200 series are the ideal choice for applications in sewage treatment plants. Their robust design with metal guides on the gate ensures reliable shut-off even with highly viscous media. The integrated cutting edge of the gate also enables effective separation of solids and deposits, preventing blockages and malfunctions. Solid media materials and fibers, which are typical for applications in sewage treatment plants, are cut through by the cutting edge before the tight seal is made against the elastic seat seal. In addition, the gate guide is interrupted along the stroke length so that contaminants can be expelled.

Thanks to their high-quality construction and low-maintenance design, GEFA knife gate valves have a long service life, even under extreme operating conditions. This not only reduces maintenance costs, but also ensures high system availability and long-term operational reliability.

DOMINO Knife gate valve AT100 (SD1)

- Face-to-face dimension: DIN EN 558 line 20

- Body: EN GJL-250 (GG25)

- Gate: Stainless steel 1.4301 or 1.4571

- Seal: NBR, EPDM, FPM, PTFE, PU ceramic fiber, graphite, etc.

- Sizes: DN 100 - DN 400

DOMINO Knife gate valve AT200 (SD7)

- Face-to-face dimension: EN 558-1 line 20/16

- Body: EN GJL-250 (GG25) , EN GJS-400-15 (GGG40), stainless steel 1.4408, 1.4539, 1.4529, etc.

- Gate: Stainless steel 1.4301, 1.4571, 1.4462, 1.4539, 1.4529, etc.

- Seal: NBR, EPDM, FPM, PTFE, PU ceramic fiber, graphite, etc.

- Sizes: DN 50 - DN 1800

High-pressure gate valves for sewage sludge drying

Sewage sludge is a by-product of sewage treatment and passes through various process stages - from thickening and digestion to dewatering and thermal utilization. Our DOMINO high-pressure gate valves are ideal for this area, as they work reliably even under high pressures and do not clog even with viscous media.

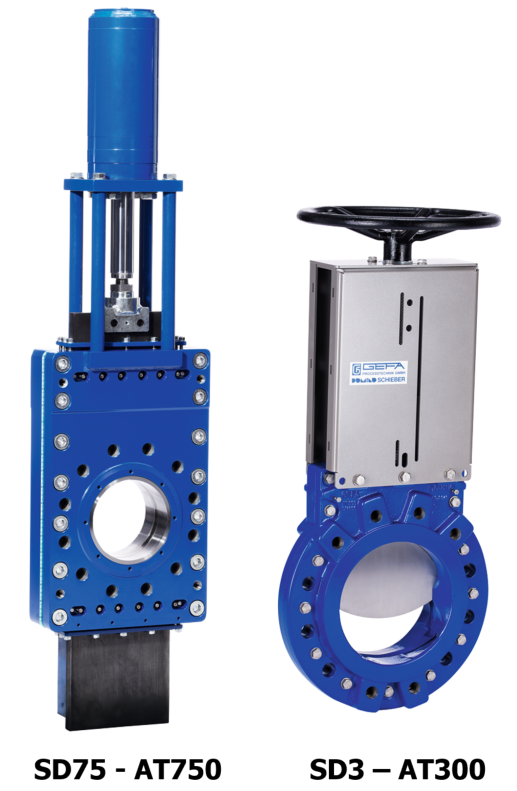

DOMINO AT300 (SD3) / AT750 (SD75) - Specialists for special applications

Their main application is in piping systems for conveying mechanically dewatered sewage sludge or biomasses with high dry substance contents. Even materials with dry matter contents of up to 50% are nowadays conveyed in piping systems with the aid of pistons, screw pumps or eccentric pumps. Due to the long pipelines and geodetic height conditions in the plants, delivery pressures of 20 to 50 bar are generated, in some applications even higher. Pipelines and especially the valve technology used must be able to adapt and withstand the extreme requirements.

In these areas, the GEFA knife gate valves of the AT300 series, which can be used at pump pressures up to max. 40 bar, have proven their worth for years. Applications include chamber filter presses or centrifuges for sewage sludge drying, storage and loading of dewatered sewage sludge or in piping systems in fermentation and biogas plants.

For the higher requirements, GEFA Processtechnik GmbH has added the AT750 series to its product range. This covers applications with operating pressures up to 100 bar. In a sewage treatment plant in southern Germany, for example, ball valves that became sluggish after a few operations due to deposits of the medium in the dead spaces and had to be removed for inspection were successfully replaced by this gate valve.

High-pressure gate valve AT300 (SD3)

- Face-to-face dimension: DIN EN 558 line 16

- Body: EN GJS-400-15 (GGG40)

- Gate: Stainless steel 1.4301

- Seal: NBR (EPDM, FPM)

- Sizes: DN 100 - DN 300

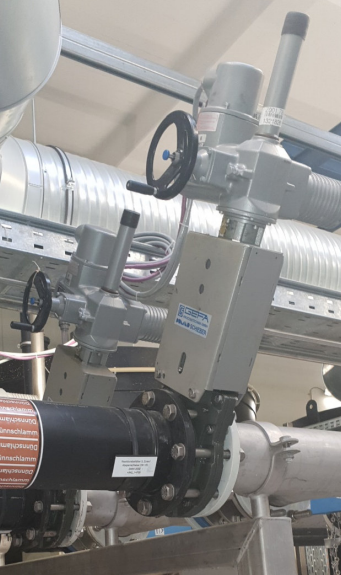

Application of the DOMINO high pressure gate valve in wastewater treatment plants

Installation of DOMINO high pressure gate valves AT750 DN 150 PN 100 as a replacement for the previously installed ball valves, which blocked after a few operations due to storage of medium in the dead spaces.

- Medium: dewatered sewage sludge, 24-28% dry matter content

- Operating pressure: max. 50 bar

- Operating temperature: 20°C

- Switching frequency: 10/year (switching without pressure)

- Actuation: E-drive Auma, rising spindle

Download here our sewage sludge flyer

Control gate valves for aeration tanks

Aeration tanks are the heart of biological wastewater treatment. Here, targeted aeration promotes the decomposition of organic substances. Our DOMINO control gate valves enable precise air control for effective oxygen input in aeration tanks and offer considerable energy savings.

DOMINO AT200R (SDR) - Precise air control for efficient aeration tanks

The AT200R control valve was specially developed for controlling air volumes in aeration tanks and sets new standards in flow control. Thanks to its innovative special control orifice, it ensures a linear control characteristic that enables precise control of the oxygen input. This leads to optimized aeration and contributes to increased efficiency and energy savings in sewage treatment plants.

Challenge in the aeration of sewage treatment plants

The biological purification of wastewater in sewage treatment plants is based on the targeted introduction of oxygen into so-called aeration tanks. There, microorganisms break down organic impurities, thereby purifying the wastewater. Precise control of the air supply is of crucial importance here. It ensures an even supply of oxygen to the microorganisms and helps to avoid over- or under-aeration. At the same time, optimum air control helps to minimize the energy consumption of the system, as inefficient aeration would be associated with unnecessarily high energy consumption.

Conventional control valves such as butterfly valves often have high pressure losses, which means that more energy has to be used for ventilation. This leads to rising operating costs and can impair the efficiency of the entire system. The GEFA-DOMINO AT200R control valve offers an optimum solution to this problem. With its specially developed control orifice, it enables a linear control characteristic and ensures precise control of the air flow - even under fluctuating operating conditions. Thanks to its flow-optimized design, the control slide valve also minimizes pressure losses, which has a positive effect on the energy consumption of the sewage treatment plant.

Control gate valve AT200R (SDR)

- Body: EN GJL-250 (GG25), EN GJS-400-15 (GGG40)

- Gate: Stainless steel 1.4301 or 1.4571

- Seal: NBR, EPDM, FPM, PTFE

- Sizes: DN 50 - DN 1200

Application of the DOMINO control gate valve in sewage treatment plants

Discover how the use of DOMINO AT 200R control gate valves as a replacement for butterfly valves on aeration tanks in sewage treatment plants not only improves the control characteristics, but also leads to considerable energy cost savings. Here, using the example of a municipal sewage treatment plant, we present the outstanding advantages of our innovative technology.

- Medium: Air

- Operating pressure: 65 bar abs.

- Operating temperature: 70 °C

- Volume flow: 3700 Nm³/h

- Pressure loss valve: 1.98 mbar at 100 %

Download here our control gate valves flyer

Filter technology for sewage treatment plants - Optimum filtration for reliable water treatment

In addition to our knife gate valves, we also offer high-performance filtration solutions that play a crucial role in the water treatment of wastewater treatment plants. Our filter systems help to efficiently remove solids, protect pumps and pipelines and increase operational safety.

Filtration in sewage treatment plants

Our filtration solutions ensure reliable removal of solids in post-clarification water and sustainably improve water quality. Discover how our filter systems contribute to operational safety and efficiency in sewage treatment plants.

Filter technology product range

From automatic backwash filters to screen filters - our filter technology protects systems, reduces maintenance costs and ensures smooth water treatment in a wide range of applications. Find the right solution for your requirements.

If you are looking for an optimally matched valve for your sewage sludge application, please feel free to contact our team of experts - our specialists will be happy to advise you!

Dirk Pollak

Product Manager

Knife Gate Valves

LinkedIn-Profil

Günter Bünsow

Product Manager

Filter technology

LinkedIn-Profil