hydrogen applications

hydrogen applications

Shut-off valves for hydrogen applications

Hydrogen – The energy of the future

The transition to climate-friendly and sustainable Energy solutions is one of the hardest challenges of our time. In this context, hydrogen is gaining increasing importance as the energy carrier of the future. Its versatile applications – from industrial production and mobility to energy supply – make it a key element in the energy transition.

Particularly, green hydrogen, produced through electrolysis using renewable energy, can significantly reduce CO² emissions and gradually replace fossil fuels. To ensure that hydrogen can be used safely and efficiently, systems, pipelines, and valves must meet the highest standards. "H2 eady" means that components are specifically developed or qualified for hydrogen applications to withstand challenges such as high diffusion rates and material stress.

Comprehensive solutions for the hydrogen industry

As a manufacturer of industrial valves, we offer complete system solutions for the production, treatment and utilisation of hydrogen. Our butterfly valves, ball valves and non-return valves are essential components along the entire process chain - from electrolysis, cleaning and drying to safe storage and distribution.

Sustainable hydrogen production and utilisation is already an elementary component of industrial chemical, Energy and gas technology and forms interfaces to process- related applications. The example of ammonia clearly shows that hydrogen is required in synthesis, but ammonia can also be an energy carrier and means of transport for hydrogen. Oxygen, which is a ‘by-product’ of hydrogen electrolysis, is also not a new challenge for us. Our Butterfly valves, ball valves and non-return valves have been used reliably in these areas for many years. Our solutions ensure safe shut-off and control of liquid and gaseous substances under demanding operating conditions.

Advantages of our shut-off valves for use in hydrogen

Process reliability with aggressive media

- Safe handling of aggressive substances such as caustic potash and ammonia

- Reliable internal tightness thanks to double eccentric technology and ball valves with strong overlap

Durability & resistance to hydrogen embrittlement

- Stainless steel materials in accordance with DIN EN ISO 15156, no elastomers in H2 contact

- High resistance at pressures up to 40 bar and temperatures up to 400°C

Future-proof performance & high flow rates

- Large nominal diameters up to DN 1000 for modern production plants

- Optimised KV values for maximum flow with reliable sealing

Certified safety & purity standards

- ATEX certification up to Zone 0 IIC & SIL consideration (EN 61508) for potentially explosive and safety-critical applications

- Defined standards for the production, cleaning and packaging of hydrogen and oxygen valves

Environmental protection & maximum safety

- Our valves are permanently technically tight, equivalent to bellows seals

- Maximum leak-tightness, confirmed by approvals in accordance with TA-Luft VDI 2440 and DIN EN ISO 15848-1

Certifications

DN 8 bis DN 1000 - from compact to high performance

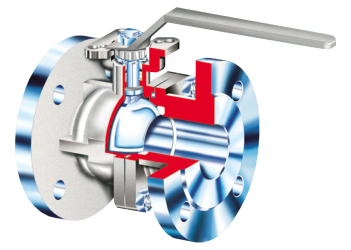

Ball valves for hydrogen applications: Compact design and full flow

Our ball valves are characterized by a compact design and a full flow for ultra-pure media. Thanks to the wide range of variants, the ball valves can be adapted to your applications and requirements.

Sizes: DN 8 to DN 150

Pressure ratings: up to PN 125

Advantages:

- Operationally proven and eliable design even in case of high pressures

- Ease of maintenance: Very quick replacements of seals due to the centre section, which can be swivelled out (DG)

- Different cleaning standards

- Full compatibility of internal parts from the DG and FG series

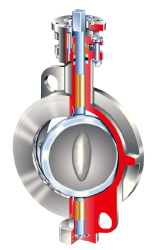

High-performance butterfly valves for hydrogen applications: Double eccentric principle for low-friction operation

Our butterfly valves based on the double eccentric principle for low-friction actuation. The high-performance butterfly valves are available as wafer and lug type valve (HG1/HG7) and double-flanged versions (HG5).

Sizes: DN 50 to DN 1000

Pressure ratings: up to PN 40

Advantages:

- Reliable sealing against high pressure and low torques due to the double offset design

- Low-wear switching characteristics

- Ease of maintenance

- Different cleaning standrads

Hydrogen drying by Adsorption

What does the use of GEFA hydrogen valves look like in real hydrogen processes? In our application example, we show how our valves contribute to hydrogen drying by adsorption.

Expert advice from the GEFA team

Do you have hydrogen applications and need advice and support? We will be happy to help you select the right valve for your hydrogen application.