PTFE-lined Butterfly Valve KG8

Technical data

Lug type butterfly valve for installation between flanges EN 1092, PN 10/16, ASME class 150. Two-piece body, selfcentring, one-piece valve disc and stem, bubble-tight up to 10 bar.The pipeline can be removed from the flange on one side.

Sizes DN 50 - DN 300

Face-to-face dimension DIN EN 558 line 20 API 609 table 1

Mounting flange DIN EN ISO 5211

Test DIN EN 12266 P10 P11 P12 Leakage rate A

Certifications CE-Marking, TA Luft, FDA approval, food certification 1935/2004, ATEX

Available materials

| Body | Valve disc |

Seat ring |

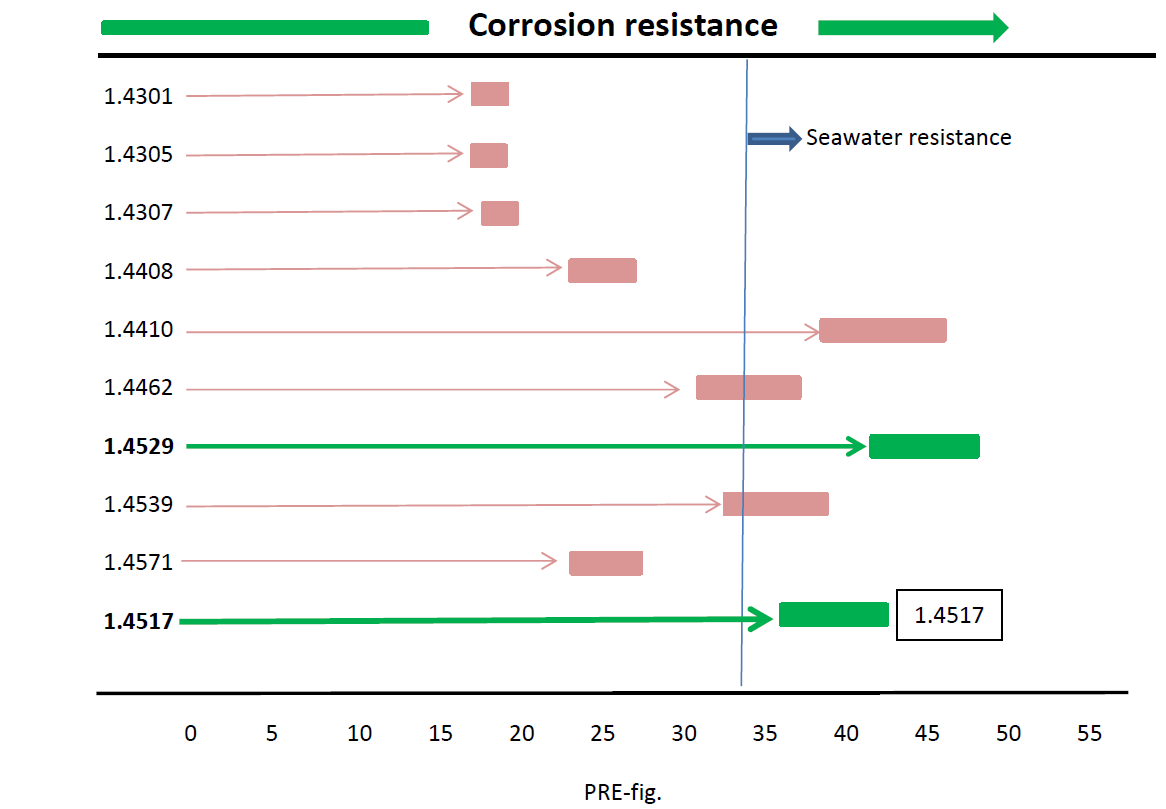

| Grey cast iron (GG25) | Stainless steel 1.4517 (polished) | PTFE |

| Ductile iron (GGG40, GGG40.3) | Stainless steel 1.4529 | PTFE/carbon |

| Cast steel (GS-C25) | PTFE lined | PTFE pharmaceutical version |

| Stainless steel 1.4408 | PTFE, conductive, lined | PTFE, conductive |

| STainless steel 1.4571 | PFA lined | UHMWPE |

| Alloy C22 | PTFE, conductive, cavity-free | |

| Titanium |

* If you have any other material requirements, please contact us!

Product information KG6/8_K16/18 (GB) (2.28 MB) Technical data sheets Request CAD