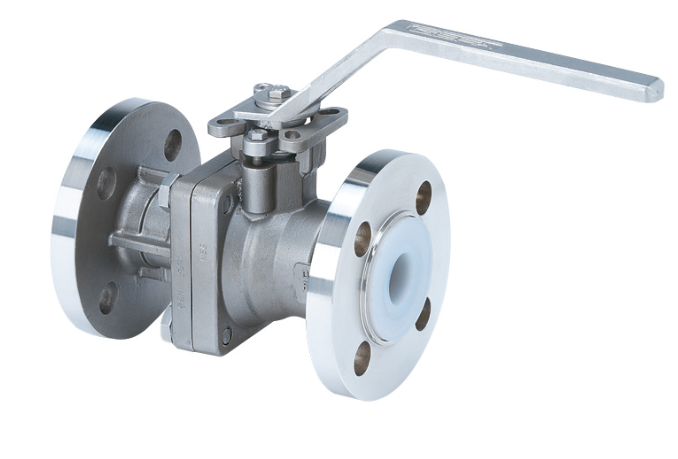

Flanged Ball Valve FGT

Type FGT (PFA-lined)

Technical data

PFA-lined flanged ball valve PN 10 -PN 40, class 150 with full bore. The material combination stainless steel 1.4408 on the outside and PFA fluoropolymer as lining coming into contact with the medium ensures a very good chemical resistance and the external corrosive influences are also considered. The interface according to EN ISO 5211 allows a costeffective automation and the direct mounting of actuating elements and actuators. The ball valve is also available according to food certification EG1935/2004.

Sizes DN 15 - DN 50

Face-to-face dimension EN 558 line 1 (DIN3202-F1)

Mounting flange DIN EN ISO 5211

Flange connection EN 1092, PN 10 - PN 40, ASME B 16,5 - class 150

Certifications CE-Marking, TA Luft,FDA approval, Food certification 1935/2004

Industries and applications

Chemical industry

Food and beverage industry

Pharmaceutical industry

Petrochemical industry

Process engineering

Ultra-clean media

Available materials

| Body | 1.4408, PFA |

| Ball | 1.4408, PFA, Ceramic |

| Stem | 1.4313, PFA |

| Seat ring |

PTFE |

| Packing |

PTFE |

* If you have any other material requirements, please contact us!

Product information - series FGT (GB) (2.04 MB) Technical data sheets Request CAD